WhatsApp)

WhatsApp)

High precision cylindrical grinding machine compared with the ordinary cylindrical grinding machine the grinding efficiency can be greatly improved and the processing quality of the workpiece can be improved thereby reducing labor costs ordinary cylindrical grinding machine models m m m1332b1000 m1332b1500 m1332b2000

Dec 21 2015 if we have a workpiece which has not exactly not right circular cylindrical shape in this situation we will prefer infeed grinding process as grinding wheel could be dressed according to the workpiece surface grinding wheel will be feed in radial direction in case of infeed grinding process

Importer of a wide range of products which include cnc cylindrical grinding machine bearing inner race grinding machine roll grinding machine internal grinder voumard 3a klingenberg worm grinding machines and cnc internal grinding machine

Supported by a hardworking team of professionals our company is engaged in presenting premium quality cylindrical grinding machine that is widely used for grinding purposes in cement ceramic fertilizer and other industries at our reliable vendors end the offered machine is manufactured by using topmost grade raw material and contemporary techniques as per the industry standards

May 08 2018 cylindrical grinding machine abstract everybody knows a tubeshaped processor is one powerful helpful thing to have as an expansion to a machine however in the event that you at any point estimated one you know they keep running into some genuine mounts of cash along these lines in view of this i set off to

China cylindrical grinding machine manufacturers select 2020 high quality cylindrical grinding machine products in best price from certified chinese engraving machine manufacturers drilling machine suppliers wholesalers and factory on

Get the best deals on metalworking grinding machines when you shop the largest online selection at currentslide of totalslides shop by machine type go to previous slide shop by machine type tool cutter grinder surface grinder cylindrical grinder in metalworking grinding tooling end mill grinding okamoto grinder

Critical to quality ho is a machine shop established in 1945 and located in waterloo ontario with particular expertise of producing very precise components most often using cnc turning grinding and honing machines measuring with cmms lasers and air gauges

Jan 27 2015 the modern cylindrical grinding machine of these days could also be utilized for the higher precision grinding process of noncircular or cylindrical contours and for this purpose the cylindrical grinding machine has path control continuous in the x caxes for example in case of for eccentric grinding

Cnc cylindrical grinding machine is composed of bed work table grinding wheel frame head frame and tailstock bed and workbench the bed is made of large round holes and shark finshaped ribs after longterm use the machine has good dynamic stiffness and static stiffness

Offering surface and cylindrical grinding for an array of intended applications including die work precision machine company inc works with molds slabs turbine blades and wire form parts we can achieve a maximum surface grinding width of 8 inches and up to 24 inches in length

Surface grinding machine for the producition of precision ground surfaces grinding machine types cylindrical grinding machines these are the most common type these are used to shape the exterior of an object such as a cylinder or a crankshaft having a central axis of rotation

Cylindrical and surface grinding of steel knight manufacturing co inc offers cylindrical and surface grinding which includes inner and outer diameter on a range of carbon steels and powdered metals we work with a range of industry verticals such as the appliance construction electrical medical and motorcycle industries

In this present work the effect of input parameters viz grinding wheel speed workpiece speed abrasive grain size depth of cut concentration of cutting fluid and number of passes has been found on the surface roughness of cylindrical grinded aisi 4140 steel has been found the other parameters like feed rate diameter of workpiece coolant flow rate etc are kept constant

Grinding of tool steel 7 internal grinding segmental surface grinding surface grinding cylindrical grinding figure 4 differences in contact length for different grinding operations stock removal rate when grinding the amount of chips removed per unit of time can most easily be expressed as mm3s this is often referred to as the stock re

The following section details our grinding capabilities and equipment we can provide cylindrical grinding and centerless grinding services if you have any questions or would like to receive a free quote please give us a call

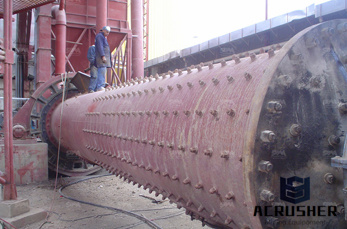

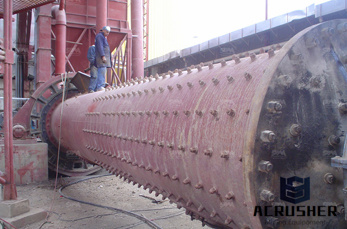

Cnc cylindrical roll grinder the spindle is made by nicrmo alloy steel with precise grinding which was installed into hydrodynamic bearing to get precise rotary nonwear performance grinding machine we are specialzed in manufacturing grinding machine

May 29 2018 the machine calculates optimal spindle rpm when the operator inputs the jobs surface footage on the controller parts and processes among recent additions in the cylindrical grinding repertoire is the replacement of chrome plating with hvof spray coatings said rob titus grinder product specialist for okuma america corp charlotte nc

Image courtesy of wikipedia if youre looking to shape the outside of an object cylindrical grinders are your target machine the ecotech cylindrical grinder is a high rigidity design for grinding small medium and large size workpieces in single and lot size production

Cylindrical grinding machine cnc surface ball lapping machine from shanghai nansensub machinery manufacturing coltd established in 1976is situated in js province nearly shanghai city area of 16000 square meters currently hired 120 employees 20 engineers and technicians included as professional in mechanical manufacturing and processing

Grinding processes external cylindrical grinding external cylindrical grinding in the external cylindrical grinding process rotationally symmetrical workpieces are usually clamped in the machine between centres and then machined with a grinding wheel at one or more outer diameters

WhatsApp)

WhatsApp)