WhatsApp)

WhatsApp)

Industrial plant these figures are to be employed when the nature of the device is such that normal operation requires a continuous supply of compressed air therefore no factor for intermittent operation has been used and the figures given represent the compressor capacity in free air output

Used to ensure that the plant is in full working order in accordance with the requirements specified in the design of the plant and includes recommissioning 30 responsibilities 31 university is overall responsible for the implementation of the uwa plant and equipment safety procedures

Pillars of the pfister wear index are the intensity of usage pneumatic conditions and the individual friction factor the identification of wear drivers and their impact patterns allowed the development of a model that indicates the condition of wear parts until now preventive maintenance was scheduled in fixed time intervals

Cement dust released during bag dumping or concrete cutting can also irritate the skin moisture from sweat or wet clothing reacts with the cement dust to form a caustic solution allergic skin reaction some workers become allergic to the hexavalent chromium in cement

As a supplemental fuel to coal only one california plant utilizes gas as a primary kiln fuel this is a relatively small plant that produces white cement the remainder of the natural gas usage is associated with boiler and machine drive end uses figure 21 cement industry end use electricity consumption process machine drive 81 process

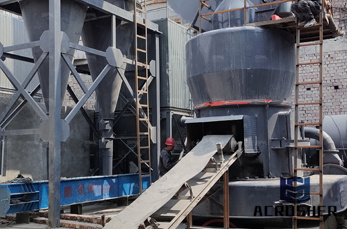

Exporter of cement plants machinery circular vibratory screen vibrating screens vibrating wire mesh screen and motorized vibrating screen offered by narayan industries medabad gujarat

Aug 30 2012 generally cement plants are fixed where the quarry of limestone is near bye this saves the extra fuel cost and makes cement somehow economical raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant there are also various other raw materials used for cement manufacturing

Jun 19 2019 use of sewage sludge in cement industry it could be an attractive business proposition for wastewater treatment plant operators and cement industry to work together to tackle the problem of sewage sludge disposal and high energy requirements and ghgs emissions from the cement industry so no negative impact on the cement quality

More than 250000 people work in concrete manufacturing over 10 percent of those workers 28000 experienced a jobrelated injury or illness and 42 died in just one year potential hazards for workers in concrete manufacturing hazard exposure to cement dust can irritate eyes nose throat and

Cement fingerprint specifically designed to help customers sustain high performance cement fingerprint provides a plant area benchmark together with a set of recommendations aimed to increase the plant performance and its energy efficiency once the customer has implemented these recommendations we have to

Ready mixed refers to concrete that is batched for delivery from a central plant instead of being mixed on the job site each batch of readymixed concrete is tailormade according to the specifics of the contractor and is delivered to the contractor in a plastic condition usually in the cylindrical trucks often known as cement mixers

Subbases may be constructed of granular materials cementtreated materials lean concrete or opengraded highlypermeable materials stabilized or unstabilized once the subbase has hardened sufficiently to resist marring or distortion by construction traffic dowels tiebars or reinforcing steel are placed and properly aligned in

Companies should be monitoring and assessing facilitylevel energy consumption to know a facilitys energy demand and environmental impact over a period of time and how that demand and costs associated with it vary by whats occurring in the plant even simple spreadsheetbased models for facility monitoring can offer benefits at the outset

Usage crushing and noise pollution is an impact i n the cement a flue gas emission from a cement manufacturing process is considered for development of co2 capture plant the cement

A model for improving plant availability has been proposed by applying this model an optimum maintenance schedule for the process plant can be formed improvement in availability of plant after employing the optimum schedule was calculated a case study of a cement plant has been used to demonstrate the methodology

1 feeding equipment after normal running 2 material shall be fed evenly in order to prevent side load or side weight increase 3 generally temperature rise o bearing shall not exceed 35 and maximum temperature shall not exceed 70 or stop and get rid of the trouble 4

Stedman machine impact crushers every stedman crusher is engineered for a maximum feed size target output size and total capacity but selecting a crusher on these criteria alone is merely half the task these can be used as a cement crusher mineral crusher and many more

Cement plant gearboxes tend to be overloaded and consequently they often overheat resulting in expensive premature wear and failure of the gears other common mechanical issues include emulsification of the gear oil due to water contamination and extreme ing

Examples of machine rates for a power saw a tractor a team of oxen and a truck are in the following tables although the machine rates in tables 35 to 38 share the same general format there is flexibility to represent costs that are specific to the machine type particularly in

Cement mill wikipedia a cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are

Hence some people think that quarry crusher machine is the key to determine success or failure of ore production line therefore the ore beneficiation plant should pay enough attention to selection of processing equipment and production management of ore crushing work related quarry crusher machine impact crusher sand making machine jaw

WhatsApp)

WhatsApp)