WhatsApp)

WhatsApp)

In grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do often the ball used in ball mills is oversize just in case

Apr 22 2016 mechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences 14during ball milling up to 80 of the energy that is generated in the mill is dissipated as heat this is why measurement and control of the temperature in the ball mills is important for example if heatsensitive products are formed that

Into fine and coarse fractions for grinding in the cement production process the fine fraction is the finished product and the coarse fraction is returned to the grinding mill for reprocessing the evolution of the technology of classifiers has seen a transition from the socalled vortex effect getting more from the cement ball mill with the

May 11 2015 a grinding mill which consumes 6070 of the total electricity consumption of the cement plant12 a grinding mill ball mill is used to grind the cement clinker into fine cement powder grinding aids are used to improve the grinding efficiency and reduce power consumption this paper discusses the grinding aids mechanism and

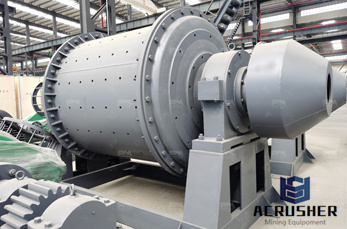

Cement mill overview a cement mill is the equipment that used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills cement clinker is usually ground using a cement ball mill this is essentially a large rotating drum containing grinding media normally steel balls

In all ore dressing and milling operations including flotation cyanidation gravity concentration and amalgamation the working principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals in the chemical and process industries grinding is an important step in preparing raw materials for subsequent treatment

Henan yu hui can supply any type of ball mill machine if you are interested in our ball millcone ball mills energysaving ball millwelcome to contact us

Mill speed critical speed mill speed no matter how large or small a mill ball mill ceramic lined mill pebble mill jar mill or laboratory jar rolling mill its rotational speed is important to proper and efficient mill operation too low a speed and little energy is imparted on the product

A ball mill grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto the material to be ground the rotation is usually between 4 to 20 revolutions per minute depending upon the diameter of the mill the larger the diameter the slower the rotation

Ball mill for grinding lime mortar ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes it works on the principle of impact size reduction is done by impact as the balls drop from near the top of the

Ball top size bond formula calculation of the top size grinding media balls or cylpebsmodification of the ball charge this calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency

Union process is the source for the most uptodate information on grinding balls and other media click the link above to view a detailed sheet outlining factors to consider when selecting grinding media along with specifications on the most common types of media

Essen ceramics is renown for manufacturing high alumina beads balls for powder mineral grinding application high quality wear resistant alumina micro bead is widely used in superfine grinding in the field of nonmetal mineral powder it is the best milling media for stirring mill sand mill and shaking mill

Jan 07 2015 cement industry cement mill notebook qatar national cement company dohaqatar 2010 na2elll slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising

Best way to determine the balltopowder ratio in ballmilling how i can get a full calculations for the journal bearing of cement ball mill cite 12th dec 2019 a ballmill and a jet

A cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills

Henan zhengzhou mining machinery coltd china mining machinery production base henan zhengzhou mining machinery coltd is leading mining equipments manufacturing in the world who has provided innovative technology and products for mine and energy of over 100 countries and district

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag grinding station cement plants metallic and concrete silos vertical mills horizontal mills pluggrind modular and portable grinding stations 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag grinding

Sweco vibroenergy grinding mills are the most versatile line of mills available today for fast lowcost particle size reduction to submicron range vibroenergy grinding action achieves higher output per input horsepower precise control of size and distribution product contamination from media and lining wear is virtually eliminated

Optimization of cement grinding operation in ball mills contact us several energy efficient options for cement grinding are available today such as vertical roller mills roller presses typically in combination with a ball mill and clinker pregrinders with ball mills

Jun 19 2014 the ball mill can grind all kinds of ores and other hard materials additionally both primary and secondary grinding with a ball mill can be applied in a variety of industries reliable and easy for operation despite the effective and powerful grinding the ball mill is a reliable and easy tool for operation the ball mill has a very simple

Mill for cement the mill shell is divided by a diaphragm coarse grinding using big balls of up to 100 mm in diameter takes place in the first com partment the peripheral wear lining is designed as a lifting or activator plate lining which with the large balls achieves a high energy input for comminution the transfer diaphragm allows

WhatsApp)

WhatsApp)