WhatsApp)

WhatsApp)

Welcome to the Concrete Surface Preparation Center. This Network hub offers services in shotblasting, grinding, scarification concrete floor surface preparation.

GRINDING ConYentional and CNC Tool Cutter Grinders Centerles Grinders, Centertype, Plain, Internal, Uniersal ID/OD, Very Large Roll Grinders

Although more widely accepted in Europe, US manufacturers are now starting to show an interest in peel grinding in two primary areas: 1) As an alternative to ...

The centerless grinding process is ideal for finishing small cylindrical metal parts that require a tight tolerance and highvolume production.

Donaldson Torit dust collectors are used for grinding, buffing and polishing applications in the metalworking industry.

You''re on a quest to make the ultimate burger, to feed the healthiest raw food diet for your pet, or create your famous homemade venison sausages that your ...

The Book of Grinding is presented in a straightforward, easytounderstand format. Complicated concepts in grinding theory are translated into practical terms.

Naresh Kumar Int. Journal of Engineering Research and Applications ISSN :, Vol. 5, Issue 1( Part 3), January 2015, ...

Turning is a machining process in which a cutting tool, typically a nonrotary tool bit, describes a helix toolpath by moving more or less linearly while the ...

QUESTION: Why can''t I find speeds and feeds tables for grinding? I''m not interested in any fancy grinding process I just want the most common speeds and feeds for ...

The grinding wheel is a cutting tool. It''s an abrasive cutting tool. In a grinding wheel, the abrasive performs the same function as the teeth in a saw. But unlike a ...

KPRIX means the combination of quality, cost and service... 4 INTRODUCTION Since 1955, Cheil Grinding Wheel Ind. Co., Ltd. has been manufacturing high quality ...

Angle grinding 101 The do''s and don''ts of cutting and grinding. Practical Welding Today July/August 2013 July 8, 2013 By: Terry Tuerk. In fabrication shops across ...

1 IsaMill™ Technology Used in Efficient Grinding Circuits Burford1 and Clark2 High intensity stirred milling is now an industry accepted method to ...

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its .

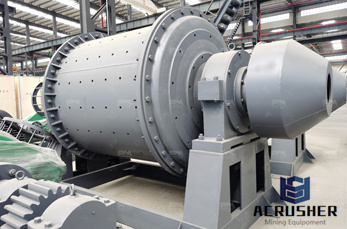

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

The right part for the job. Every grinding mill is unique. They do however have one thing in common. They need to be operational. Liner changes need to happen quickly ...

Technical information for abrasive grinding for metallographic and metallography analysis

CONTENTS SECTION PAGE Grinding Process 1 Types of Bonds 5 Abrasive Types, Properties and Usages 7 Elements of Abrasives 10

About Grinding and Polishing Mechanical Preparation. Mechanical preparation is the most common method of preparing materialographic specimens for microscopic examination.

Most of my work is at the highend of the New England custom home market. For the jobs I do, in Boston brownstones that even today sell for several million dollars ...

This class will teach you the most common grinding processes and describe the machines that is used, chucking type grinders are generally used only for high ...

Holemaking is a class of machining operations that are specifically used to cut a hole into a workpiece. Machining, a material removal process ...

SMW Autoblok Workholidng Pvt. Ltd. is a subsidiary of SMW Autoblok Group, having Head office at Pune, India.

WhatsApp)

WhatsApp)