WhatsApp)

WhatsApp)

Corn Wet Milling vs. Corn Dry Milling ... High Energy Ball Milling | Union Process® Inc ... Union Process is the trusted, knowledgeable source on high energy ball ...

on particle size and surface morphology of Zeolite by wet ball milling treatment ... imposed to the wet milling process at 2–8 h, the peaks occurred at 3360, 1641 ...

what process is ball milling. Posted on May 29, 2013 by shuijing. ball mill process | Mining, Crushing, Milling. ... What is wet and dry process ball mill?

Wet milling: Wet milling with IKA''s inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for ...

Ball Mill/Ball Mill Grinder/Wet Ball Mill/Ball Milling . Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing ...

ball milling process, wet charging ball mill Grinding Mill. wet magnetic separation and agglomeration stages,BAOBAB RESOURCES PLC . the milling,, requirement for ...

Grinding Media Grinding Balls ... Union Process is the one ... grinding media that are used for milling same materials (silicon carbide ball to mill silicon ...

Ball Milling Pretreatment of Corn Stover for Enhancing the Efficiency of Enzymatic Hydrolysis ... are designed to optimize the main factors in the ball milling process.

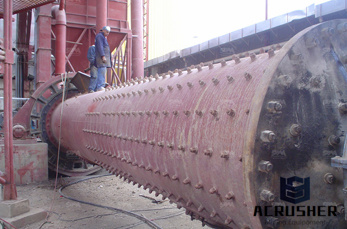

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground ...

Wet Milling, Comminution, and Emulsifying equipment styles include Horizontal Bead Mills, Rotor Stator Homogenizers, and Ultrasonic Liquid Processors.

Official FullText Paper (PDF): Effect of Ball Size and Powder Loading on the Milling Efficiency of a LaboratoryScale Wet Ball Mill

Ball Mills of for qualigied products and superior service, gives you the best Ball Mill ... of ball milling methods: dry and wet process ...

Grinding in Ball Mills: Modeling and Process Control ... a ball milling device usually consists of a ... The grinding process can also take place in dry or wet ...

wet milling process for sale 11979 ... glass, ceramics and other industries for power grinding and milling process. Ball mill can grind various stones, ...

The results show that the antimony nanoparticles can be prepared successfully by wet process of ball milling. When the ball milling speed is 150 r/min and the...

Ball Mill Promas Engineers. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process. Product Description Ball ...

Calcium phosphate bioceramics preped from wet chemically calcium oxide and water in planetary ball mill as a first step of synthesis provides a highly dispersed ...

The Quest for Nanotechnology and the Evolution of Wet and Dry ... (traditional tumbling ball ... A media milling process produces contamination due to wear of ...

A ball mill can also be helpful in the process of cold welding, ... The ball mill can be used in the processing of wet or dry materials, ... FAB 3R. All rights ...

Preparation of ultrafine dispersions of zinc oxide by simple ballmilling: Optimization of process parameters. ... Wet ballmilling .

Synthesis of Nanomaterials and Nanocomposites ... dry or wet milling, ... first describe the equipment and some of the process variables used for high energy ball ...

Theory and Practice for . Jar, Ball and Pebble ... milling is a process for reducing the particle size ... This formulation is for wet milling where as dry milling ...

Wetmilling in planetary ballmill. view as. API. Rank By. ... Wet milling is an attritionbased process in which the insoluble material is dispersed in the aqueous ...

Wet ball milling in presence of PAA in water results in lot of reduction in ... Due to two competing process of breakage and agglomeration there is ...

WhatsApp)

WhatsApp)