WhatsApp)

WhatsApp)

We produce a wide range of highalumina cements and calcium aluminate have customers in more than 60 countries around the world.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Burning in a kiln – formation of cement clinker. The next step in the process is to heat the blended mixture of raw ingredients (the raw mix) to convert it ...

Cement Mill Noise Level and Attenuation Report Page 3 2. Introduction This study was conducted to evaluate noise levels of both conventional ball mills and vertical ...

Cement Equipment corp. likes. Cement Equipment ( maintenance, inspection ) Cement and clinker Chemistry Cement plant Manufacturing process

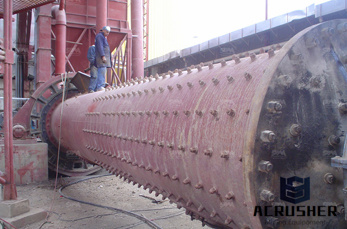

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

Full Vent System Clinker Collector Gypsum Separator Collector To Product Storage Mill Collector OSepa Separator Primar Air Secondary Air Finish Mill Mill

Kumardhubi Factory. Kumardhubi is situated in the heart of coal iron belt near Dhanbad in Jhark... more

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

Specialized foundry of premium wear parts for aggregate, recycling, mining and cement plants. Blowbars, cones, jaws, liners, kiln inlet, cooler grates, ceramic insert ...

CEMENT PLANT / CEMENT GRINDING UNIT . We are manufacturers and exporters of cement plants like mini cement plant, clinker grinding unit, cement bagging plant and .

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

8 476 AU : IPRM 2007 : SectIon 8 : conSUMAbleS WARnInG Welding can give rise to electric shock, excessive noise, eye and skin burns due to the arc rays, and a ...

Calcium aluminate cements are cements consisting predominantly of hydraulic calcium aluminates. Alternative names are "aluminous cement", "highalumina cement" and ...

Contact HIC,Indian manufacturer of Universal brand industrial rubber productsconveyor rubber belt,conveyor belt roller,flat belt,shaft coupling,rubber hose,vbelt ...

White cement manufacture and history ... Burning Process. In principle, any type of kiln used for grey clinker production can also be used for white.

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

The general sheet gives the production in t/h of a cement mill in function of: the cement fineness and the general dimensions of the mill. A calculator is also ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

CEMENT ThyssenKrupp Technology: Build to Last. ThyssenKrupp has supplied equipment, engineering and services for all of the major global cement producers, as well .

WhatsApp)

WhatsApp)