WhatsApp)

WhatsApp)

hammer mill for size reduction, ... Wet logs cause low combustion efficiency, ... The Beginners Guide To Pellet Production

Crusher Hammer Detail Information ... efficiency. The hammers do most ... The hig h manganese ball mill Liner Plate is widely used for all kinds of minerals with strong,

Hammer Crusher. Sand Making Series ... Grinding Efficiency + Pdf. ... The specific selection function effect on clinker grinding efficiency in a dry batch ball mill ...

energy efficiency in a hammer mill business plan for stone crushing plant,sand determine efficiency of hammer mill, ... hammer mill efficiency pdf ...

Hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Material is fed into the mill''s chamber through the feed

hammer mill efficiency pdf; Crusher mill. PF Series Impact Crusher; B Series VSI Crusher; B Series Deep Rotor Vertical Shaft Impact Crusher; HP Series Hydraulic ...

Download PDF Download. ... Comminution features in an impact hammer mill. ... The effect of the feed rate and the rotor speed on the mill efficiency in terms of ...

EFFECTS ON BOILER EFFICIENCY STANDARDS OF PULVERIZING COAL Fred D. Lang, Tim Golightly and David Rodgers, Tom Canning Exergetic ...

Design, Economics Richard Zinn ... Feed mill • Efficiency ... Roller Mill vs Hammer Mill From L McKinney, KSU Roller mill yields fewer

small hammer mill 420 Series. ... high efficiency and low noise. ... Online Wood Pellet Manufacturing PDF Status. 24 March, 2017.

Advantages of hammer crusher are as follows: ... The Handling Materials and Application Field of Hammer Mill: Handling Materials: pebble, ... Free Download PDF

Determine Efficiency Of Hammer Mill jacobson hammer mill model 2438 India. Hammer Mill Efficiency Crusher Mills Cone Crusher Jaw .

EV hammer impact crusher 4 1 Hammer rotor 2 Inlet roller 3 Hammers 4 Outlet grate 5 Rails for sliding grate in and out 6 Breaker plate adjustment

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

wheat or barley using a hammer or a roller mill. ... in terms of feed efficiency. The diet particle size ranged from 657 to 968 microns (832 microns on average).

Particle reduction technology BY GREG ALLES Opening in ... ingredient can also affect the grinding efficiency of the ham ... the hammermill screen.

STUDY THE EFFECT OF SOME OPERATIONAL FACTORS ON HAMMER MILL El Shal,; Tawfik 2; ... /s hammer tip speed and the milling efficiency takes .

Hammermill. American Pulverizer Hammermills offer flexibility, uniform reduction, and economical operation. Hammers are reversible—with two or more crushing ...

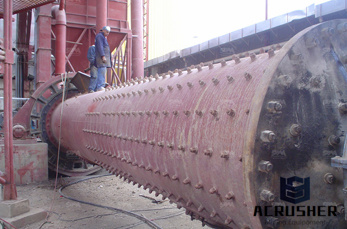

PCZ heavy hammer crusher is widely used in many industries such as mine, metallurgy, building material, highway, railway, water conservancy and chemical industry, and ...

Influence of hammer mill screen size and grain source ... feed intake, daily gain or feed efficiency due to hammer mill screen size. Feed efficiency was

Development and Testing of a Hammer Mill ... The machine is of hammer mill type. In this case, there is hammerlike ... to determine its work ability and efficiency.

DESIGN, FABRICATION AND TESTING OF A LABORATORY ... since it is part of the objective to fabricate a hammer mill and compare the efficiency with a standard .

The view of the hammer—mill related stress model—how high is the frequency ... milling efficiency is a product of stress intensity and stress numbers, ...

WhatsApp)

WhatsApp)