WhatsApp)

WhatsApp)

The healthy operation of an elevator means that it does not leak the product when it carries into the elevator and provides the desired capacity with the determined sufficient and minimum energy consumption in the targeted life at this point the use of a welldesigned elevator and correctly selected buckets are the main factors in the successful operation of the elevator

Different types of bucket elevator design there are multiple types of bucket elevator to consider too the type of bucket elevator designed depends on the application for example swinglink bucket elevators this bucket elevator is a chain and pendulum type system and can be used to convey a range of products and include multiple inlets

What are factors that will affect cement mill output hydration kinetics modeling of portland cement what are factors that will affect cement mill outputinfluence of chemical composition of cement the composition of cement is the most important influencing factor of all there exist mills 24 conducted a series of tests and in 3 it is an experimentally obtained quantity

Vertical mill gearbox ngcs vertical mills are designed to withstand high torque and extreme conditions these rugged gearboxes are essential to transmit power reduce the rotating speeds and supporting the mill

Oct 22 2015 a brief presentation on cement plant process and instruments used in cement plant it is then moved to the kilin feed12 and then moved to preheater12 with the help of bucket elevator 14 coal mill particles in the gas stream are charged by a highvoltage direct current field which is generated from the discharge electrodes

Bucket elevator 2 there is a demand for the increasing the capacity of new and old elevators particularly for handling grain the factors that influence the capacity of an elevator are bucket type shape and discharge characteristics optimum speed in relation to pulley size shape of head and boot material characteristics such as size shape and density angle of repose coefficient of

The ball mill users all know that they should take good care of ball mill in order to extend its service life there are many factors that influence ball mills service life we will explain the specific use of ball mill and related factors following

The closedcircuit grinding system of the ball mill is shown as follows materials mixed in a certain proportion will firstly enter the cement ball mill for grinding and then be sent to the powder concentrator by bucket elevator the powder concentrator divides the materials into coarse and fine materials

Selecting sprocket for ball mill selecting sprocket for ball mill selecting sprockets for ball mill selecting sprocket for ball mill drive sprocket for cement mill no 1 outlet elevator meet selection technical information step 5 select the number of teeth on the small sprocket porcelain lined ball mill ball mill for sale dry ball mill get price sprocket for ball mill

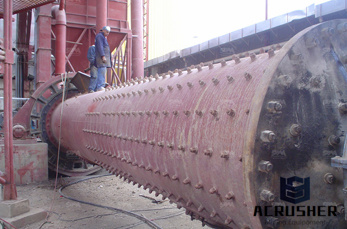

The modernisation included the existing belt bucket elevator to the raw mill the intralogistics specialist beumer offered its innovative heavyduty bucket elevators permitting higher conveying capacity and longer service life thanks to this new technology the existing bucket elevator could be easily modified

The ball mill has the advantages of simple structure stable performance and large crushing ratio 3100 which can be used for wet or dry paper introduces some factors that affect the grinding efficiency of ball mill 1 movement pattern of steel ball in cylinder exactly speaking to some extent the motion of the grinding medium in the cylinder affects the grinding efficiency

India beumer group has supplied a hgbwhc 1250 x 1753m belt bucket elevator to the acc cement plant in wadi beumer says it is the highest such bucket elevator in the world with a distance of 1753m between the centres the size of this system enables a flow rate of around 600thour to be achieved supported by highstrength steel wire belts

And feeding materials such as granulated blastfurnace slag gbs with a high moisture content may require drying preferably using waste heat high freelime clinker must be blended into mill feed with circumspection to ensure that the resulting cement is not expansive a maximum composite free lime for the cement should be established and

The two chambers have a certain quantity of ball charge of different sizes from 17mm to 90 mm the mill discharge is fed to a bucket elevator which takes the material to a separator which separates fine and coarse product the latter is sent to the mill inlet for regrinding and the final product is stored in concrete

Sep 11 2018 but with the finer less permeable charge mill bypass was encountered at a mill throughput of 280 tph these experiments proved that a permeable ball charge is required in the second compartment of a finish grind mill to accommodate high mill throughput and high circulating load levels if this is what the plant wants to do on the circuit

The clinker grinding process in cement manufacturing is one of the processes that factors in the effectiveness of the products and efficiency of the industry this article therefore aims to explain the need for a clinker grinding plant as well as insights into the process involved in clinker grinding in cement manufacturing processes

What is cement mill also called cement ball mill cement mill is the key equipment that grinds the crushed materials the cement ball mill produced by fote adopts high chromium alloy steel or double medium quenched steel liner which has the characteristics of high quenching hardness and high

By observing the current curve of the main motor in the control room vertical ultrafine mill and the current curve of the circulating bucket elevator the current of the vertical ultrafine mill is about 95100a while the vertical current of the vertical ultrafine mill is 157a that is the effective power of the vertical ultrafine mill only

When designing a bucket elevator there are more variables to be consider that can be listed here it should be noted that a small mistake in calculating the required hp of a small low capacity bucket elevator may not result in a unit failure but a small mistake on a large high capacity bucket elevator may result in a catastrophic failure

Feed material is ground in the ball mill discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams coarse and fines the coarse fraction is sent back to the mill and the fines are collected in cyclones and or a baghouse as finished product

To storage and then to the finish mill is similar to that used to transport raw materials eg belt conveyors deep bucket conveyors and bucket elevators to produce powdered cement the nodules of clinker are ground to the consistency of powder grinding of clinker together with

In second compartment which is longer in size l15d classifying liners are used to ensure media classification along the length of mill with large size balls near mid partition and smaller balls at mill discharge end ball mills are of bucket elevator type for cement grinding material is taken by conveyors to a separator where coarse was

WhatsApp)

WhatsApp)