WhatsApp)

WhatsApp)

handle ball scats with ease are lighter in weight and safer for maintenance are lower in cost than heavy metal parts so whatever the preference for a rubber or metal pump the mc pump will ensure the best wear life and operational safety right three 550 mcr mill circuit pumps installed at a copper mill along with

Note specifications serial numbers and prices are believed to be correct and should be used as a guide only quotes are typed when machine is purchased often from seller specs location condition price accessories and specs can change please check with us to verify any detail in question

Jun 06 2014 what is the best way to model a ball end mill feature i know there must be many ways what method do you use on flat surface complex surface and cylinder on top i used a simple 2d extrude cut with fillet on bottom lower i used a swert cutbut not sure how to get the rounded start and end conditions

Oct 17 2018 i need to model a cut using a ball end mill along a path nonlinear i think i need to model the spherical cutter body then sweep that body along a path any ideas adam scheible may 6 2009 454 pm correct answer never mind i just noticed the solid sweep setting thanks for all your advice on resolution and small radii

The mill is used primarily to lift the load medium and charge additional power is required to keep the mill rotating 813 power drawn by ball semiautogenous and autogenous mills a simplified picture of the mill load is shown in figure 83 ad this can be used to establish the essential features of a model for mill

The model uses a user selected method to define the milling characteristics of the ore and the ball mill the diagram shows the default drawing of the limn mill with all of the streams that must be connected to the unit the physical location of the streams connecting to the mill is unimportant the default ball mill access window

Union process manufactures a broad line of particle size reduction equipment such as wet and dry grinding attritors and small media mills in laboratory and production sizes our particle size reduction equipment is customizable to meet your specific milling and dispersion needs

Welcome to the milldrawings web site which is rebuilt from the old a0 technical drawing services site my name is john brandrick i live in whitland carmarthenshire i am a retired draughtsmanengineer i worked in the construction process industries for over 50 years and was very lucky as drawing had always been my hobby and i was able to do it almost every day during my

Grinding in ball mills modeling and process control an improved c ontact model for ball mill simulation by th e penggerusan dengan ball mill replika menghasilkan indeks kebundaran 027

Table of contents autogenous grinding circuitssag vs ball mill advantagesag sag mill grinding compared which is besttesting for product size size reduction is the most expensive operation in most mills crushing and grinding usually require the greatest portion of capital costs and often make up 6070 percent of total mill operating costs as shown in figure 1 selection of the proper

In grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do often the ball used in ball mills is oversize just in case well this safety factor can cost you much in recovery andor mill liner wear and

Autocad inventor model cut produced by ball end mill taking arbitrary 3d path may 17 2012 ive been trying to model cut produced by a ball end mill taking an arbitrary 3d path i know how to do this for 2d paths and this has been discussed a couple of times on this forum but i have had little to no success extending this to paths in 3d

Free cad and bim blocks library content for autocad autocad lt revit inventor fusion 360 and other 2d and 3d cad applications by autodesk cad blocks and files can be downloaded in the formats dwg rfa ipt can exchange useful blocks and symbols with other cad and bim users

About 34 of these are mine mill 10 are grinding equipment and 3 are other food processing machinery a wide variety of model mill options are available to you there are 42660 model mill suppliers mainly located in asia the top supplying country or region is china which supply 100 of model mill respectively

Mill partsprice list mp5e7041 bearing 6910vv 75 mp5e7042 snap ring for emill 5vk 5 mp5e7043 bull gear bearing spacer 22 mp5e7048 ball bearing gear sleeve 85 mp5e7056 bearing locknut mp5e7057 bearing sleeve spacer 45 mp5e70572 bull gear washer for e5vk 15 mp5e7058 wave spring washer 10 mp5e7059 bull gear shift pinion shaft 25

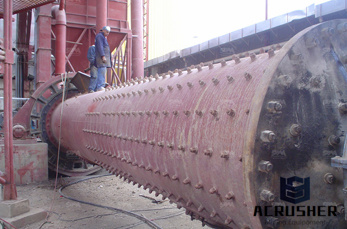

Ball mill is the key equipment for recrushing the materials after they are primarily crushed ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement silicate product new building material refractory fertilizer black and nonferrous metals and glass ceramic industry

Jun 14 2011 it will help a lot to have an actual end mill in hand the larger the better to inspect the profiles lip angles and the way the flutes end as a starter you could try a search for endmill in the user library on 3d contentcentral and download a model to see how they did it

Dec 16 2019 im trying to model a 15 center cut end mill but i cant figure out how to draw the flutes accurately anyone have some tipsideas thanks in advance

Model available for download in model0x00007fc072afd860 format visit cgtrader and browse more than 500k 3d models including 3d print and realtime assets end mill free 3d model free 3d models

A stamp mill consists of a set of heavy steel ironshod wood in some cases stamps loosely held vertically in a frame in which the stamps can slide up and down they are lifted by cams on a horizontal rotating the cam moves from under the stamp the stamp falls onto the ore below crushing the rock and the lifting process is repeated at the next pass of the cam

The ball mill is a tumbling mill that uses steel balls as the grinding media the length of the cylindrical shell is usually 115 times the shell diameter figure 811the feed can be dry with less than 3 moisture to minimize ball coating or slurry containing 2040 water by weight

Ball mill power draw predicted from the denver slide rule kw 0 200 400 600 calculated ballmill power draw from the m odel derived kw data compared line yx fig 2 comparison of the ball mill power draw from the denver slide rule and the proposed model dashed line corresponds to yx

WhatsApp)

WhatsApp)