WhatsApp)

WhatsApp)

The effective load rating ofa linear ball bearing is dependent upon the orientation of the ball rows with respect to the load direction the load ratings in the dimension tables are indicative of the minimum load rating orientation load case i for knz kbz and load case

Web title iso ansi first choice product mill 4 series 2 12 cutting diameter d1 04330 maximum cutting depth ap1 max m4d250l1107s075l157

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing a ball end mill is constructed of a round cutting

Timken ok load astm d2509 lbs 40 45 50 55 60 55 trained customer service and technical support industrial customers turn to mill grease timken ball bearing pillow block grease extreme low and high temperatures severe loads corrosive media slow to moderate speeds

Chase online lets you manage your chase accounts view statements monitor activity pay bills or transfer funds securely from one central place if you have questions or concerns please contact us through chase customer service or let us know about chase complaints and feedback

7 in grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do often the ball used in ball mills is oversize just in case

Typically bottlenecks in a circuit can be found in the equipment for comminution transportation or classification they are possibly preventing crushing screening and milling equipment from operating at their optimum performance levels in the first post of the series we covered the importance of measurement and assessments to increase value per tonne here we will take a deeper look on

Mills reliability was restored to as new solution leveraging its oem knowledge of mill design designed and executed an innovative method of replacing the mills shell the shell was replaced one section at a time without a complete teardown metsdesign of horizontal grinding mill

Union process is the source for the most uptodate information on grinding balls and other media click the link above to view a detailed sheet outlining factors to consider when selecting grinding media along with specifications on the most common types of media

224 vais headspace gauge set go nogo field made in white city oregon usa making firearm parts and chamber reamers since 1957

How to increase ball mill capacity why do we need such a high recirculating load on our ball mill the ball mill circuit circulating load ratio clr and the overall circuit capacity or increasing the circulating load to 500 brings that value up to 26 times for a

Tinamitem offers high wear resistance reduced friction and excellent prevention of cutting edge build up it provides superior material removal rates and tool life when used in high performance operations with difficult to machine materials like titanium

The maximum size is 5 acres tunnel sites a tunnel site is a subsurface rightofway under federal land open to mineral entry it is used for access to lode mining claims or to explore for blind or undiscovered veins lodes or ledges not currently claimed or known to exist on the surface a tunnel site can be up to 3000 feet in length

Oct 01 2015 chip load equals the feed rate divided by the spindle speed multiplied by the number of cutting flutes and chip load that varies widely or is too low or too high will cause tools to wear out too fast chip or break maintaining constant chip load is a particular problem when machining the 3d contours that are characteristic of moldmaking

The ball mill this can be caused for example by required inspections performed on the sag mill shell bearings etc which leads to a relative short shutdown of the sag mill if the ball mill would be equipped with fixed speed motors then they will have to be washed out isolated and stopped

Approximate ball loads can be estimated by assuming 300 lb per cu ft of ball volume and a total load equivalent to 40 to 45 per cent of the mill volume rod loads average about 40 per cent of mill volume and a figure of 400 to 425 lb per cu ft of rod volume should be taken

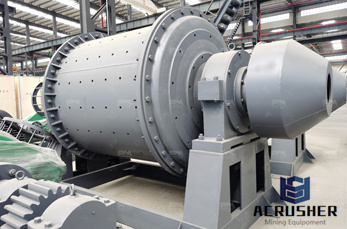

The type of mill that is used for grinding ore in a modern concentrator is the wet tumbling mill these mills may be divided into three types rod mills ball mills and autogenous mills in the first type the rod mill the ore is introduced into the mill

The equations to calculate critical speed and maximum speed of ina ball screws are as follows buckling load a shaft under compressive axial load is subject to potential buckling it is recommended that the maximum axial load on the ball screw be limited to 50 of the buckling load limits due to static and dynamic load ratings must be observed

Radialcontact ball bearings are designed to support radial loads angular contact bearing designed to support combination of radial and axial loads thrust bearings designed to support axial loads roller bearings have higher load capacities than ball bearings for a given size and are usually used in moderate speed heavyduty applications

Dont fear high speed hard metal high speed machining hsm of hardened die steels should not be feared but embraced many people feel that hard metal machining is a black art but with a few basic principles it is not only profitable but also a straightforward machining process

Bid live at new mill capitals beverage processing and packaging equipment auction final inventory reduction of the largest us beverage equipment dealer auction

Based on the critical speed chart the best choice appears to be a srt since the lead of the srt ball screw is 250 the maximum rpm needed to achieve the maximum travel rate would be 1728 rpm check column strength of screw use previously determined values in combination with the column strength chart load 65 lbs

WhatsApp)

WhatsApp)