WhatsApp)

WhatsApp)

Minehaul minings underground workhorse minehaul is fenner dunlops premium multiply conveyor belt designed specifically for the demanding nature of the heavy duty underground mining industry manufactured with msha cfr title 30 part 14 certified fire boss fire retardant compounds which meets and exceeds msha requirements

Fire safety in the industry on a mine site fire hazards may occur in and around process plants underground conveyors static and mobile plants draglines workshops substations monitored control rooms and switch rooms in many cases nongaseous and gaseous fire suppression systems are the preferred systems installed to

A video has emerged of the conveyor belt fire at the cape lambert port facility last thursday it is believed that the fire originated from hot work during a shutdown at the rio tinto jv robe river facility the robe river facility separates lumps and fines that are predominantly exported to chinas coastal and north china niche steel mills

Jul 18 2018 18 july 2018 with six mineworkers killed and 48 injured in an underground fire at palabora copper mine in the limpopo province caused by a burning conveyor belt increasingly south african mines are becoming deathtraps for mine workers

This type of fire protection is extremely specialized and a team of highly off coal belt conveyor belt protection quarry and mining instrument solutions for the coal mining industry conveyors protected by our belt protection system for conveyor belt fire acts conveyor belt mining requirement for fire protection in coal conveyors in the

Fire suppression systems are the first line of defense after a conveyor belt fire has started in an underground coal mine between 2000 and 2009 twentyfive fires in underground coal mines were caused by friction of conveyor belts against pulleys drives rollers idlers and bearings msha these fires were often not detected for

Flame resistant conveyor belts approved by msha under code of federal regulations title 30 part 14 the conveyor belts applicable to this listing were tested and approved as flame resistant under the code of federal regulations title 30 part 14 these conveyor belts are approved for use in underground

Pertaining to flameresistant conveyor belt fire prevention and detection and use of air from the belt entry richard e stickler acting assistant secretary of labor for msha stated this final rule calls for improved flameresistant conveyor belts to better protect miners in underground coal mines

Mine health and safety act guideline for mandatory code of practice for safe use of conveyor belt installations for transportation of mineral material or personnel

Msha has determined that some belt takeup storage units do not have adequate fire protection because belt conveyor takeup storage units are not provided with sufficient protection and the wide belts may shield the sprinkler from suppressing a belt fire the federal mine safety and health act of 1977 and 30 cfr part and 30 cfr

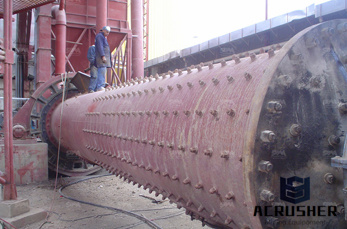

This months spotlight feature article from the pages of the october 2013 issue of international mining magazine focuses on equipment and technology application for conveyors in mining john chadwick examines some impressive new installations and new component technologies for conveyor systems

The mine improvement and new emergency response act of 2006 miner act established a technical study panel the panel to provide recommendations on the utilization of belt air and new technology that may be available for increasing the fire resistance properties of conveyor belt used in underground coal mines the panel report recommended use of the belt evaluation laboratory test belt

Construction conveyor mini conveyor systems mining conveyor concrete conveyor firewood conveyor mining conveyors access construction equipment is the manufacturers of portable belt conveyors portable construction conveyors built to withstand the rugged conditions of any job site

Mines safety and inspection act 1994 and has been endorsed by the mining industry advisory committee the act mine fires and minimise the impact of fire outbreak while chapter 7 summarises the content of a suitable underground conveyor belts collapsed bearings or excessive friction

Conveyor belt fire safety a new proactive way of thinking h schmitz fire detection along the conveyor belt installation as the belt material can however also burn and give off noxious mine health and safety act 1996 act no 29 of 1996 regulations chapter 8 machinery and equipment

Long known throughout the mining industry for its scandura and georgia duckconveyor belt brands fenner dunlop americashas combined the best of both to produce a range of mining conveyor belts that consistently outperform the competition in rigorous above ground and below ground mining applications but not only has fenner dunlop united the

Fire detection and suppression on underground conveyor belt installations background on 20th september 2004 a fire occurred on a conveyor belt installation underground at a platinum mine in the western limb of the bushveld complex

Mining company palabora copper confirmed on monday that six people have died at its copper mine in phalaborwa following a fire that broke out at its underground conveyor belt operation during the

5 while fire and explosion risk assessments have to be carried out both below ground and on the surface this guidance relates primarily to fire and explosion risks below ground however the general principles should be applied to those buildings and equipment on the surface of a mine where a fire or explosion could prejudice safety below ground

The mines health and safety act legislates and regulates the use of underground conveyor belts particular reference is made to belts used in coalmines which should be made from fireresistant

Risk assessment for belt conveyorrelated fatal incidents in the us mining industry article pdf available january 2008 with 8407 reads how we measure reads

With reference to a host of both state and australian legislative requirements in managing and mitigating risks for both the health and safety associated with the operation of conveyor belts in a mine one of the foremost considerations is given to the competent regular visual inspection of the system to detect and act on any overheating

Premium conveyor belts high quality conveyor belt for a wide variety of service applications designed for use in hard rock mining log handling aggregate minerals and other critical applications manufactured in widths to 72 1800 mm tension ratings from 160 piw to 1250 piw

Suggest fire risk prevention and control measures in belt conveyor index termsheat sensor fire sensor water pump a belt conveyor consists of an end i introduction 11 conveyors now a days belt conveyors system is not only used in cement industries but also applied in mining industries

WhatsApp)

WhatsApp)