WhatsApp)

WhatsApp)

Exporter of Grinding Media Cylpebs, Forged Steel Grinding Media Balls, Hyper Steel Grinding Media Balls and HiChrome Grinding Media Balls offered by Mufaddal ...

A wide selection of ROLLER MILLS available. Call us for more details.

The general sheet gives the production in t/h of a cement mill in function of: the cement fineness and the general dimensions of the mill. A calculator is also ...

ABB in cement From quarry to dispatch . We start with the best people, engineering expertise and over a century of knowledge and knowhow of electrification and ...

Ash Grove Cement and Related Materials (Manufacturing Process), Portland cements are hydraulic cements composed primarily of hydraulic calcium silicates.

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying

TECHNOLOGICAL UPGRADATION OF CHUNAR CEMENT GRINDING UNIT,, CHUNAR CEMENT FACTORY (A Unit of Jaiprakash Associates Ltd. India)

Gelmaxx offers the ultimate water removal and slurry solutions for you, turning cement based slurry into reusable water and recyclable solids.

Aims to improve cement and concrete and its uses, and raise the quality of construction. Page includes industry news magazine.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Summarises the hydration process of Portland cement and describes the principal cement hydration products.

Latest News. The management is giving high priority to training activities in a wide range of topics. Also, the onjob training proved to be very successful.

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

Welcome to AIA Engineering/Vega Industries. Specialist in Cement, Mining, Power and Aggregate Businesses

With an annual capacity of 63 million, UltraTech Cement is the largest cement company in India and amongst the leading producers of cement globally.

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

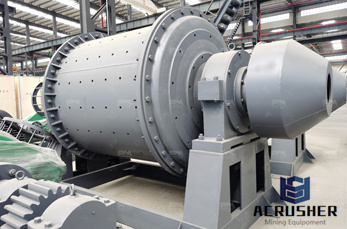

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Lucky Cement Limited (LCL) is one of the largest producers and leading exporters of quality cement in Pakistan, with a production capacity of million tons.

Drying and Primary Grinding. The essential additives quartz, sand and iron ore are added to the homogenised material and this mixture is then ground to a powder with ...

1 2 3 4 5 6 7 8 9 10 F Production and facilities information COMPOSITION AND PRODUCTION OF CEMENT Cement is made by crushing and grinding calcium carbonate (limestone ...

WhatsApp)

WhatsApp)