WhatsApp)

WhatsApp)

How to choose grinding ball for mill high quality grinding media balls usually have the performance of accurate size high hardnessgood toughness low abrasion and low e hardness is up to 6065hrc core hardness is less 12hrc than surface hardness g grinding ball advantages the sample manufacture equipment needs less investment

Best way to determine the balltopowder ratio in ballmilling which formula is best to use for determining the number of grinding balls to charge the grinding balls are also made of

Specifically the coarse grinding box should choose high chromium ball fine grinding box can choose low chromium wet grinding low chromium ball or forged steel ball should be chosen because the wear resistance of high chromium ball cannot be fully reflected in the case of the point of view of wear resistance cast

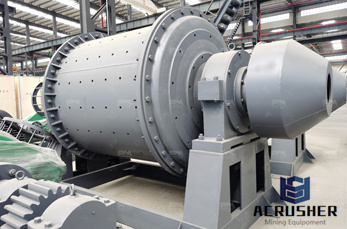

Jun 14 2018 the function of a ball mill to perform its functions the ball mill operates on the principle of impact and attrition this principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact the major components of the ball mill include a shell that is hollow and is suspended on its axis

Better efficiency starts with better grinding youve already gone through the work to bring the ore to the mill now its time to recover as much precious metal as possible grindingexpert automatically adjust feed rate mill speed and water addition to reduce upsets eliminate grindouts and increase tonnage in sag ball mills we

After the raw material melt and the composition of molten iron accords with the standard of grinding ball production then start to make grinding balls we call this process as molding the balls producing size is from dia10mm to dia150mm also includes casting cylpebs and

Grinding materials to a nanoscale is an important aspect of quality control and rd azom speaks to dr tanja butt from retsch about the benefits of using high energy ball mills instead of planetary ball mills what was the background for the development of your high energy ball mill the

July 25 2017 liners grinding ball size match will directly affect ball mill output product quality and metal consumption a reasonable match is determined by physical and chemical properties of grinding material ball mill structure and product fineness requirement

Improved ball mill grinding system to improve grinding efficiency 3 plus home efficient classifier quality of steel balls determines the ball mill life steel balls is the lifeblood of the ball mill steel balls is an essential accessory steel balls is generally divided into two types casting and forging they are not the same degree of wear

Silicon carbide balls are very highcost grinding media that are used for milling same materials silicon carbide ball to mill silicon carbide materials to avoid contamination they are only available in 5mm10mm 15mm and 20mm sizes they are a special order item

Grinding ball for initial assembly sag mill refers to the grinding balls charged in the mill before the sag mill reaches the design capacityor normal production grinding balls for ball mill ball mill is a essential equipment for further grinding the material after it is crushed

Finally we must consider the nature of the planetary ball mill grinding materials material hardness brittleness shape and size of the grinding ball grinding process has a very important impact if the above factors are all taken into account then the damage of the grinding ball can be greatly reduced

Ball mill is partially filled with free moving media balls which can be made of steel stainless steel ceramic or rubber and the media balls are in different sizes smaller grinding balls for fine calcium carbonate and larger media balls for coarse calcium carbonate

Oct 12 2017 sag mill make use of steel balls included with some large and hard rocks for grinding these mills utilize the balls in making the large fragments of materials broken into pieces the ball charge of a sag mill is about 9 to 20this process takes place inside the large rotating drum of sag mill which is filled with balls partially

Rod mill and mill are two kinds of equipment commonly used in grinding order to obtain higher grinding efficiency and effectively improve the effect of dressing it is necessary to choose the right grinding e ball mills and rod mills are similar in appearance many people do not know much about their specific differences making them difficult to choose

Grinding balls for mining are generally used to break down secondary materials such as rock cement and stone during the extraction of ores and metals aisi steel grinding balls for ball mill applications typically have a tolerance of 005010 and a density of 770 to 795

94 x 061 balls the optimum number of grinding balls is 285 however the ball diameters vary due to wear therefore the total ball number should be adjusted from time to time to ensure a total mass of 20125 grams the grinding jar of the bond index ball mill measures 12 x 12 and has wellrounded corners module rod mill

Knowledge how to choose the right planetary ball mill and related grinding jarsmedia balls 1 to choose the right machine volume alumina bullk density 1 gcm3 volume mass density 1 1 1 as the grinding material covers 13 of the mill pot volume mill balls cover 13 of the mill pot volume and the left 13 for grinding space

This article on choosing milling media for a ball mill by ned gorski is a side article that goes with the ball milling 101 g media cautions in his book ball milling theory and practice for the amateur pyrotechnician lloyd includes a section on casting your own lead media

The choice of grinding ball material is mainly to see the ball mill the general grinding ball and ball mill the best choice for the same material when the grinding sample is determined to be suitable for the use of a material of the ball mill the grinding ball material can be determined to come ball material can not be the same with the ball mill the general combination of the following

The size of grinding media plays a key role in overall performance of the grinding circuit larger grinding media has a smaller grinding surface area but offers a heavier weight thats generally used to break larger ore small grinding media has a larger grinding surface area generally chosen to help make smaller ore smaller

Mar 29 2019 ball mills are a special instrument used to break up hard solids into a fine powder they are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder ceramic material crystalline compounds and even some metals can be ground up using a ball mill

In this article alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were investigated silica ore was used as the test material

The tm 300 drum mill is used for the preparation of granules and powders the grinding process is performed either in dry or wet conditions the drum mill can be operated either as a ball or as a rod mill by using the corresponding module a sufficient number of balls or rods is required for an effective grinding process

WhatsApp)

WhatsApp)