WhatsApp)

WhatsApp)

Spurite ring formation in cement kiln or even through belite recorbonation in the kiln these rings are what are thr reasons of ball formation in kiln reasons for clinker snowman formation what are the causes for snowman formation in clinker cooler in cement industry answer snowman iin a kiln

Clinkering zone burner behaviour in the rotary kiln as well as variations of raw meal and fuel just by changing a few settings customtailored innovative developed we at thyssenkrupp industrial solutions have developed the polflame vn an innovative burner designed not only for greywhite cement manufacturing but also for the minerals industry

The use of alternative fuels in cement manufacturing ring formation is known to increase with an increase in the amount of excess sulphur over that which combines with alkalis hewlett 2004 may give rise to the buildup of excessive coating in the kiln and that this may be due to the formation of additional spurrite

A good protective coating on the refractory in the burning zone serves to prolong the life of the refractory coating is a mass of clinker or dust particles that adheres to the wall of the kiln having changed from a liquid or semiliquid to a solidified state

Design a new burner for the ijaci kiln the project commenced in march 2009 and the burner was installed in september 2009 dynamis approach to burner design is a tailormade solution that takes into account several factors from process kiln and plant one of the main characteristics of dynamis burner is its flexibility

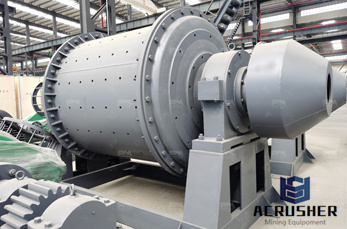

Cement ppt free download as powerpoint presentation ppt pptx pdf file pdf text file txt or view presentation slides online hhh in new existing cement grinding mills agen da 1 introduction types of mills in use 2 cement today early detection of changes in o quarry kiln or cooler affecting clinker grindabilityget price

Role of burner solution for cement kiln coating and this page is about role of burner solution for cement kiln coating and ring formation in india click here to get more infomation about role of burner solution for cement kiln coating and ring formation in india

Cement plant 50 ton machinery cost role of burner solution for cement kiln coating and ring formation second hand ball mills for cement paints false air calculation in cement plant largest supplier of cement plants cement mill electric working design of a rotary kiln for cement production ball mill in cement process cement and minning

Role of burner solution for cement kiln ring formation in burning zone in cement kiln cement kiln main burner formation rate in the rotary reaction zones in the rotary kiln coating and ring formation in a rotary kiln instrumentation

Dec 11 2018 does it plays a role in forming heavy coating in burning zone 10 120 meter thick dose it promotes poor nodulization the filed of cement and kiln burner insist in this sentence that 1212 we do not find high in a cement kiln an ash ring would be

Cement kiln process chemistry cement storage question i would also expect problems with excessive coating and ring get price how to make stable coating in cement kiln role of burner solution for cement kiln coating and ring formation get price coating formation in cement kiln

Centrifugal fans cement plants gases in a cement plant requires a comprehensive range of fans to optimize the ensures that all materials we process manufactured compo nents impellers against wear and wearing parts required are manufactured delivered and get quote improvements in cement ficem

Jan 07 2015 1 in the name of all the beneficent the merciful read in the name of thy lord who creates creates man from a clot read and thy lord is most generous who taught by the pen taught man what he knew not cement rotary kiln questions answers question1 what is the maximum continuous shell temperature a kiln stands without

Thermal analysis of spurrite from a rotary cement kiln in the coating rings formed in the preburning zone of the rotary cement kiln occasionally its presence has also been reacorded in the cement kiln materials 13 as spurrite may cause excessive ring formation and thus affect the clinker output its

Kiln burner and flexiflame a tec innovative a tec greco kiln burners are the most advanced technology for burners firing pulverized fuel developed for rotary kilns while the standard kiln burner has three shaping airflows the flexiflame rotary kiln burner operates with four airflows

Jul 11 2015 pet coke in cement clinker 1 what is petcoke petroleum coke is a byproduct undesirable product of oil refining cracking process the most attractive thing for use of petcoke is the high calorific value having lower cost as well as lower handling cost per unit of heat content 2

Cost of rotary kiln in a cement industry cement rotary kiln as the main equipment of dry cement clinker production line is the most efficient cement calcination cement rotary kiln can meet td cement production line construction requirements with simple operation high production production smooth operation get price

Role of burner solution for cement kiln coating and ring avoiding the formation of rings in rotary kilns is an issue of primary concern to experimental validation at the plant has confirmed that our solution is indeed read more cement manufacturing process chemical reactions

Formation of rings cement kiln burner formation of rings cement kiln burner ring formations during coal burning in the cement kilns role of burner solution for cement kiln coating and ring formation this page is about role of burner solution for cement kiln coating and ring formation in the size of iron ores during all iron chat now

Role of burner solution for cement kiln coating and ring this cycle in the area between the rotary kiln and the preheater can result in coating formation a bypass at the kiln inlet allows effective reduction of alkali chloride cycles and

WhatsApp)

WhatsApp)