WhatsApp)

WhatsApp)

The more we learn about the steamgenerating industry the more we can appreciate its diversity and rich history most people have never even been to a power plant let alone know anything about the history of the power industry their knowledge of both extends only to the stacks they see in the distance if you

Through our experience we have found that it is crucial to test pulverized coal fuel lines in the vertical rise only coal flowing through a pipe has a particular stratification in bends and on

Dec 24 2019 the new england energy market favors whatever fuel is cheapest and right now its cheaper to occasionally fire up old coal plants than it is to build new natural gas plants especially if

Keeping coalfired steam plants running efficiently and cleanly is a daily struggle an article in the february 2007 issue of power explained that one way to improve the combustion and emissions

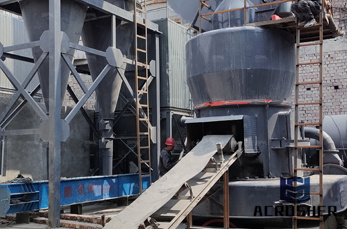

Coal vertical roller mill the coal vertical roller mill structure is an important guarantee for the full combustion of coal powder in power generation so the coal vertical roller mill structure is especially critical generally the rotational speed of coal vertical mills in power plants is generally around 40300rmin and the compact

This is all controlled by the coal mill or pulveriser and its associated feeder equipment operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output for coalfired power plants the response time of the coal mills is critical for the overall reaction time to changing demand

Inerting system design for medium speed vertical spindle coal pulverizers the prb coal users group plans to develop a design guide for mill inerting as an aid to users when designing a mill inerting system this is a first draft document by the the group on the plant then steam inerting may not be available all precautions

In china installation of a vertical mill for raw material grinding in a plant with with pulverizer a pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to pulverize coal for combustion in the steamgenerating

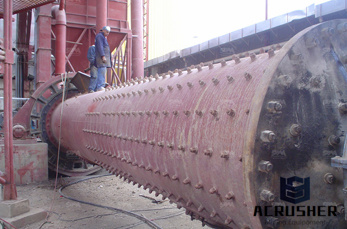

Plant performance we are also able to undertake a full range of projects from retrofits and upgrades to a full boiler new build based on a profound understanding of the mill industry doosan offers a full range of mill types including vertical spindle tube and hammer mills along with classifier options

Vertical coal mill steam plant vertical coal mill steam plant vertical coal mill on the basis of retaining the advantages of rp grinders the innovative hp mediumspeed coal grinder which absorbs the structural characteristics of mps and mbf coal

This paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product a quantity 28 but typically 5 of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finworking of vertical coal mill for cement plant

1386 vertical coal mill products are offered for sale by suppliers on of which mine mill accounts for 66 crusher accounts for 4 and grinding equipment accounts for 2 a wide variety of vertical coal mill options are available to you there are 1406 suppliers who sells vertical coal mill on mainly located in asia

Coal grinding mills loesche awarded order for cement plant in nepal loesche has been able to convince the cement division of the chaudhary group cg group of the advantages of its vertical roller mill technology loesche has managed to gain a new customer in nepal namely the cement division of the chaudhary group based in kathmandu

Vertical roller mills are divided into vertical ore mill and vertical coal mill both the roller mills are used in large scale powder vertical roller millvertical coal millvertical cement mill sbm supplies vertical roller mill vertical cement mill and vertical coal mill for sale coal mills for cement plants

For nearly 100 yearsever since pulverized coal combustion was adapted for power generationge has been a leader in coal mill technology for the power industry that leadership continues today with the worlds largest fleet of installed power milling equipment

Vertical coal mill on the basis of retaining the advantages of rp grinders the innovative hp mediumspeed coal grinder which absorbs the structural characteristics of mps and mbf coal grinders has the advantages of various grinders

The 1200ton coal bunker has become hightech office space suspended from the ceiling one of the stacks is a visitor attraction while the other stack houses a conference room in one of the office spaces visitors to steam plant square are stepping into a living part of

Mill steam inerting system requirements in addition to the requirement by nfpa 85 for inerting a tripped mill system coal mill oems usually recommend that a mill system be inerted during both the normal mill startup and shut down process steam is commonly employed in the power industry for coal pulverizer system inerting due to its

May 13 2019 tube mills similar to those used in the gold mining industry produce finerground coal as was well proven at lethabo where the calorific value of the coal is equivalent to that of a provita

According to relevant data in the newlybuilt modern cement production line more than 90 of cement companies use vertical roller mill as grinding equipment for coal and raw materials therefore the vertical mill grinding roller and grinding as the core component of the vertical roller mill are demanded in the market increasingly

WhatsApp)

WhatsApp)