WhatsApp)

WhatsApp)

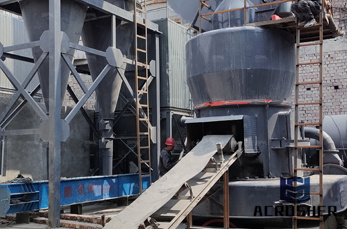

Cement Equipment Manufacturer. ... Cement Grinding EquipmentCement Grinding Equipment As a specialized cement grinding ... and reduces heat consumption by ...

The energy use is dominated by coal and petroleum coke consumption, ... Cement Grinding and Distribution ... Canadian Cement Industry 2008 Sustainability Report. 2008.

grinding processes, help to decrease theenormous energy consumption of cement prod cement flour production is immense. About 110 kWh/t is necessary for cement grinding

Schneider Electric Case Study > A Cement Manufacturing Facility Big Picture Strategies Contribute to Energy Efficiency in the Cement Industry I 3

electric consumption cement grinding. ... Cement Grinding Machine Power Consumption. Comparing ball mills and VRMS for cement grinding World Cement 26 Feb 213 By ...

CEMENT INDUSTRY Output of a Seminar on Energy Conservation in Cement Industry Sponsored by United Nations Industrial Development Organization (UNIDO)

electric consumption of concrete crusher, energy consumption in cement production Stone Crusher . Concrete ball mill media for crushing rock ... so that the ...

Cement Kilns: Size Reduction and Grinding. In the cement industry, natural raw materials are processed to produce an end product which is a fine powder.

Lafarge Schneider Electric delivers continuous improvement energy strategies for worldclass cement innovator (China) Customer Profile Founded in 1833, Lafarge boasts ...

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

Cement mills are normally driven by electric motors. Modern installations draw power of 210 ... vPower consumption for Cement Grinding alone CII Estimate ~ 1000 MW ...

electric system of cement grinding mill plant ... The energy consumption by the cement industry is estimated at about consumes electric power for the mill, ...

Energy Efficiency and Saving in the Cement ... which accounts for 74% of the energy consumption in global cement ... Of the cement production chain steps, grinding ...

The dry process needs to evaporate water when Japanese cement production process is ... Consumption rate = Electric power consumption/ Cement ...

Raw Material Grinding,Cement Horizontal roller Grinding mills ... This has resulted in low electrical energy consumption in cooling air fans and also in ...

Reducing the Energy Required in Grinding Clinker to Cement – Some ... carried out in many plants leading to decrease in energy consumption per tonne of cement.

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Reduce Energy Consumption: Cement Production How conducting manufacturing energy assessment can help identify a wide range of changes to help reduce consumption.

CEMENT ADDITIVES G reen materials can ... finish cement grinding process. Chemical processing agents like ... reduced electric energy consumption on total CO

cement grinding electricity consumption manufacturer in Shanghai, China. cement grinding electricity consumption is manufactured from Shanghai Xuanshi,It (cement ...

Cement grinding with HoromillCosts Benefits . Parent Process: Finish Grinding; Energy Savings Potential: Power consumption can be reduced by ...

Home > electric consumption cement grinding india. electric consumption cement grinding india. iron ore crushing 1; remaining copper waste in san gwann malta;

electric consumption cement grinding . Cement mill Wikipedia, the free encyclopedia. The emergence of Portland cement in the 184s made grinding considerably ...

Collaboration and shared objectives between Lafarge and Schneider Electric ... Improvements in the cement finish grinding ... of cement plant energy consumption ...

WhatsApp)

WhatsApp)