WhatsApp)

WhatsApp)

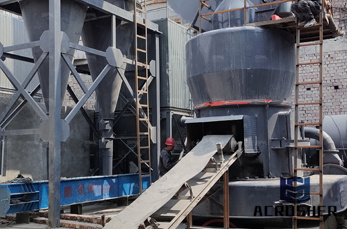

Modeling and simulation of ball mill coalpulverizing system abstract the paper presents a mathematical model and its matlabsimulink realization for ball mill coalpulverizing system bmcps based on the analysis of mass and energy balance the physical models for all controlrelated subprocesses of bmcps are developed respectively

Show full abstract shaker ball mill dynamics simulation and the grinding model the dynamics simulation is used to find out how the number of collisions the total kinetic energy and the rate

Dynamic modelling and simulation of ball mills modeling and simulation of ball mill coal 2011 the paper presents a mathematical model and its matlabsimulink realization for ball mill coalpulverizing system bmcps

Dynamic modeling and simulation of a sag millpebble crusher circuit by controlling crusher operational parameters minerals engineering 127 2018 98104 paper c li haijie magnus evertsson mats lindqvist erik hulthn gauti asbjrnsson and gram bonn dynamic modelling of a sag mill pebble crusher circuit by

1 introduction semiautogenous grinding sag mills are presently one of the most widely used alternatives in the field of mineral size reduction as a result of their comparative advantages such as higher processing capacity lower physical space requirements and lower investment and maintenance costs as compared to conventional circuits

Inproceedingshajati2011ana titlea novel approach to optimize grinding circuits modelling strategy to monitor ball mill particle size distribution data at lakan plant authorarman hajati and sied ziaedin shafaei and m noaparast year2011 arman hajati sied ziaedin shafaei m

WhatsApp)

WhatsApp)