WhatsApp)

WhatsApp)

How does the blast furnace work? ... The furnace temperature is also high enough to decompose limestone ... The furnace is heated constantly and is recharged with ...

The iron ore, coke and limestone ("charge") is fed into the blast furnace from the top. Why is it called the blast furnace?

A blast furnace charge consists of coke, ore or sinter, and limestone. These materials must be in lumps of a certain size (4060 mm). Larger lumps prolong the process of reduction and fluxing. Smaller lumps block the fluegas passages and prevent a uniform descent of melting materials in the furnace.

Why is coke added to blast furnace during the extraction of iron? ... Why is limestone added to the blast furnace in the manufacture of iron? ewste Edit.

Coke, ore and sinter are fed, or ''charged'', into the top of the blast furnace, together with limestone. A hot air blast, from which the furnace gets its name, is ...

Barbed wire is a fencing material consisting of a metal cable with regularly spaced sharp projections. The cable usually consists of two wires twisted around each ...

AQA GCSE Science C1 notes 1. Summary Notes Prepared and compiled by Steve Bishop 2. AQA GCSE SCIENCE Chemistry C1 summary notes Page 2 of 32 ...

Why is steel not produced in a blast furnace? ... What is the purpose of limestone in a blast furnace? ... Can we charge 100℅ sinter in blast furnace?

limestone used in blast furnace. ... why limestone is charged in blast furnace. Smelting furnace used to extract metals from their ores, ...

By Hardarshan S. Valia, Scientist, Ispat Inland Inc. INTRODUCTION A world class blast furnace operation demands the highest quality of raw materials, operation, and ...

Sep 16, 2008· What is the use of limestone in a blast furnace? ... Why is limestone added to a blast furnace during the extraction of iron ... and charged it with ...

ArgonOxygen Decarburization (AOD) What? A process for further refinement of stainless steel through reduction of carbon content. Why? The amount of carbon in ...

SBB''s steel glossary is great for finding the definition for any steel term associated to the industry.

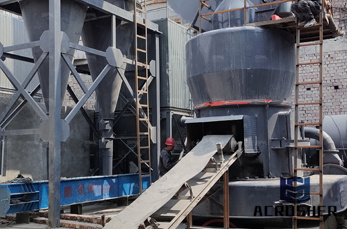

The Blast Furnace Plant . Now that we have completed a description of the ironmaking process, let s review the physical equipment comprising the blast furnace plant.

limestone used in blast furnace. Blast Furnace Limestone « Furnaces. Extraction of iron use blast furnace, ... why limestone is charged in blast furnace.

How Steel is Made: a Brief Summary of a Blast Furnace: There are two types of metals, ferrous nonferrous. Ferrous comes from, or contains iron, while NonFerrous ...

The more advanced way to smelt iron is in a blast furnace. A blast furnace is charged ... the furnace, and the calcium in the limestone ... HowStuffWorks by email ...

The subject content of this specification is presented in five sections: How Science Works the three sections of substantive content, Chemistry 1, Chemistry 2 ...

Why do we use a limestone as flux in ... Can we charge 100℅ sinter in blast furnace? If no than why and if yes than why we charge only 7080 ℅ sinter in blast ...

Limestone – Its Processing and Application in Iron and Steel Industry Limestone is a naturally occurring and abundant sedimentary rock consisting of high levels of ...

How it works: The Blast Furnace ... This iron rich ore can be charged directly into a blast furnace ... The limestone descends in the blast furnace and ...

In a blast furnace why are the coke and limestone ... The blast furnace is charged at the top with a mixture of iron ore, coke, and limestone. ...

Aardvarks (Orycteropus afer) are probably the most endearingly doofylooking animals ever to grace the African continent. These Seussian snufflers look like someone ...

Ever notice how Christopher Nolan''s movies (Interstellar, Inception, The Prestige) feel like an anxiety attack? Well, maybe that''s overstating things a bit. But ...

WhatsApp)

WhatsApp)