WhatsApp)

WhatsApp)

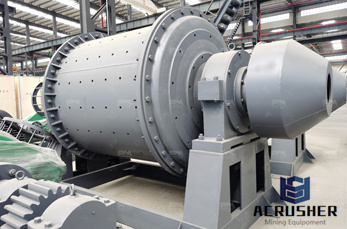

The grinding efficiency of ball mill is low the treatment capacity is low the production energy consumption is high the product fineness is unstable and so on which are the problems that most concentrators will encounter how to effectively improve the grinding efficiency of ball mill is an important problem

Addition of pebbles to a ballmill to improve grinding efciency because the consumption of small pebbles was too high addition of pebbles to a ballmill to improve grinding efficiency

Sep 18 2012 in summary select the best rotation speed of the ball mill filling rate and highquality steel ball and be careful to draw the ore particle size characteristics curve in order to determine a suitable size of the steel ball ball ratio and gradually mastered the production complement ball law is an effective way to improve the ball mill efficiency

Improving energy efficiency in barrick grinding circuits grinding semiautogenous grinding sag ball mill energy efficiency greenhouse gas the lifters and also reduced the modeled impact of the ball charge on the also provides the opportunity to better trim the sag mill speed and power to

If there are more small pieces the smaller diameter should be more since large ball are used for crushing the small balls for materials fine grinding dua highefficiency and savingenergy ball mill adopts rolling bearing substituting for sliding bearing which can save energy 1020 compared with sliding bearing the discharge size is 08

The method to improve the efficiency of ball mill the method to improve the efficiency of ball mill an appropriate increase in moisture ore grinding cavity also can increase the efficiency of ball mill work 2 quote price

The grinding efficiency of ball mill is low the treatment capacity is low the production energy consumption is high the product fineness is unstable and so on which are the problems that most concentrators will encounter how to effectively improve the grinding efficiency of ball mill is an important problem in this paper 10 methods to improve efficiency are summarized

The ratio of the barrel length to the diameter of the ball mill is small and in most cases the ratio is only slightly greater than one in addition the rotation speed of the rod mill cylinder is lower than the working speed of the ball mill of the same specification so that the medium inside is in a sloping state rod mill ball mill

Bench top ball mill small ball mill ball mill manufacturer supplier in china offering bench top ball millsmall ball mill good price metalworking fluid tapping torque simulation evaluation teser aviation fuel lubricity evaluation testerlubricating oil friction and wear tester and so on

Also the grinding efficiency of ball mill will reduce if the steel balls are too small even the collision probability is relatively high but the energy of single steel ball is very small which cannot efficiently grind the ore particles also leading to the reduction of grinding efficiency

Small grinding media represents the best potential to improve grinding efficiency how do the small grinding media perform in industrial grinding mills the use of small grinding media in regrind mills proved that finer grinding can be achieved at lower energy consumption in ball mills smaller grinding media versus 25 mm media generate a

Mill grinding ball mill a typical type of fine grinder is the ball mill a slightly inclined or horizontal rotating cylinder is partially filled with balls usually stone or metal which grind material to the necessary fineness by friction and impact with the tumbling e now how to improve the grinding efficiency of the ball mill

The milled product has a relatively fine particle size and the production efficiency is small the overgrinding phenomenon of the grinding process is severe and the grinding efficiency is also significantly lower however the overflow ball mill has a simple structure is inexpensive and is suitable for fine grinding equipment so overflow

Ball from the feeding part discharging part turning part and driving part reducer small transmission gear motors electrical control and other major components grinding mill hollow shaft with steel lined with removable rotary gear hobbing by casting the body inlaid cylinder liner wear has good abrasion resistance

Chromium is easy to be corroded and lost in the processing of wearresistant grinding media ball so the efficiency of grinding is low it is obvious that wet grinding is more efficient than dry grinding therefore the effective use of wearresistant grinding media balls can greatly improve the efficiency and reduce the cost

5 ways to improve grinding efficiency of ball mills news dec 26 2017 several factors affect the efficiency of a ball mill for cement grinding in this article we shall be looking at some of these factors that have been proven to influence grinding efficiency mill geometry and speed according to bond 1954 the g read the rest

How to improve ball mill grinding or by improving the efficiency of the grinding mill environment through the media sizing percent solids liner design etc buy laboratory small plant process equipment we have all the laboratory and plant equipment you need to test or buildoperate your plant

Mini vertical planetary ball mill is a necessary device of hightech materials mixing fine grinding sample making new product development and small batch production tencan planetary ball mill owns small volume high efficiency low noise and functional features which is a ideal equipment for rd institution university enterprises

Apr 01 2017 read addition of pebbles to a ballmill to improve grinding efficiency minerals engineering on deepdyve the largest online rental service for scholarly research with thousands of academic publications available at your fingertips

WhatsApp)

WhatsApp)