WhatsApp)

WhatsApp)

Cement ball mill is mainly used in grinding of ... Grinding efficiency, the most direct benefit is the finished powder maximize was promptly elected, reduce cement ...

Modern Processing Techniques to minimize cost in ... whereas Cemax Mill is mainly for cement grinding. The mill can be used ... possible to reduce the heat ...

Cement grinding Vertical roller mills ... • the feed to a cement mill is often ... curve for cement ground in an OK mill. In order to reduce the ...

» how to reduce energy in the cement mill; Home; Our Capability; solutions; Product; OUR PEOPLE CUTURE; CAREERS; ... can help to reduce power use in cement kilns.

how to reduce energy in the cement mill . Energy and ... the energy consumption in a cement mill was ... The vertical roller mill is expected to reduce power ...

increasing of production efficiency of cement mill. The following is our company''s popular mining equipment, ... how to reduce energy in the cement mill.

How to effectively reduce the energy consumption of cement mill. ... Cement mill ventilation can exhaust water vapor and fine powder to prevent balling and blocking, ...

Ball Mill; Cement Vertical Roller Mill; Cement ball mill; ... Cement Vertical roller mill ... to reduce duplication of milling, ...

Noise By Cement Mill. ... after fed into cement kiln. LM series vertical mill is just . and reduce noise. ... ball mill, cement mill, ...

Cement ball mill plays an important part in cement production industry. ... So the methods about how to reduce the cement ball mill power consumption are more and ...

cement plant to reduce preheater ... Estimates suggest that the Spanish cement industry could reduce its specific ... electrical drive for ball mill in cement plant;

reduce consumption of cement. reduce consumption of cement, Besides the ordinary crushing grinding machines, mining equipments also include many very professional ...

... Vertical Cement Mill, Cement Vertical Roller Mill,Vertical Mill for Cement, ... can reduce the delivery period of cement vertical roller mill greatly. ...

... Cement Mill,Cement ... ensure the economical investment for the cement production line. ... Measures have been taken to save energy and reduce ...

Cement Grinding Mill Process. ... improving with numerous innovations with a view to improve productivity and reduce power ... Coal Mill Cement Process ...

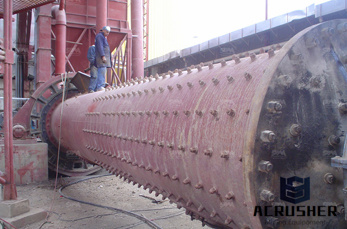

Grinding in Ball Mills: Modeling and Process ... Grinding in ball mills is an important technological process applied to reduce ... The mill is driven by a girth ...

How to reduce the system electricity consumption of ball ... By controlling the best fineness and cement quality to reduce the ... the mill effective and cement ...

If the temperature of grinding cement is too high, you can use a cement cooler to reduce it. ... and greatly reduce the outlet temperature of cement ball mill, ...

A cement mill (or finish mill in ... so highalite clinkers reduce grinding costs, ... with the cement finished in a single chamber ball mill. This gives good cement ...

how to reduce in cement mill. ... Plant»howto reduce specfic power consumption in power consumption in cement FOR CEMENT MILL . productivity and reduce power ...

Previous Product : Reduce cement mill high temperature measures. Next Product : Application of energy saving technology for ball mill . Check the corresponding services :

cement mill for cement plant grinding mill ... Its closed production line makes it possible to reduce its ambient dust pollution to less than 50mg/Nm3.

Home > Mills > how to reduce in cement mill. Products. Crushing Equipment. PE Series Jaw Crusher; PEW Series Jaw Crusher; HCS Series Cone Crusher; HP Series Cone .

ABB in cement From quarry to ... Efforts to reduce energy demands, by ... ABB in cement Raw mill Quarry Coal mill Cement mill Packing and distribution Cement silos .

WhatsApp)

WhatsApp)