WhatsApp)

WhatsApp)

Description whether steel and aluminium for vehicle manufacture cement for construction industrial minerals in aggregates coal as energy or pigments for colourful living mineral raw materials have countless applications in our world

Mar 24 2015 magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force this separation technique can be useful in mining iron as it is attracted to a magnet magnetic separators are widely u

Technique of magnetic separation it consists of a large electromagnet through which mineral mixtures are passed on a metal trough by varying the strength of the magnetic field or the slope of the tough different minerals can be separated the magnetic sepamagnetic separation for the mining industry

Jul 09 2019 1 types of copper sulfide ore 1 single copper mineral its ore characteristic is relatively simple and the only useful component that can be recycled is copper the gangue minerals are mainly quartz carbonate and silicate 2 coppersulfur ore called copperbearing pyrite in addition to copper minerals iron sulfide can be recovered and the main mineral of sulfur is pyrite

Mining separation magnetic separation and sensor sorting solutions for improved throughput and recovery rates in ore sorting and mineral processing from traditional and trusted magnetic separation equipment right through to innovative sensor sorting technologies we help our customers achieve their goals with sustainable solutions

Eriez publishes educational white papers feature articles and case studies in all industries served browse and download them here world authority in separation technologies

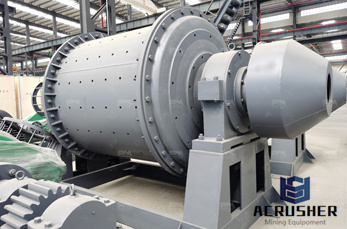

Magnetic separation for the mining industry magnetic belt we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment

However the rare earth magnetic separators are relatively inexpensive and can produce magnetic fields around 6000 gauss so when looking for a process to recover valuable minerals magnetic separation should not be overlooked if some of the material is magnetic or paramagnetic

Master magnets are manufacturers and suppliers of industrial magnets and magnet separators for more information contact us on 01527 65858 experts in magnetic separation metal detection and electrostatic separation technologies with world class test and laboratory facilities magnets for the mining minerals industry industrial

Magnetic separation has two major applications in mineral processing plants the removal of tramp iron which would deleteriously affect subsequent processes from an ore stream this is usually achieved by a low intensity magnet suspended above or at the head of a conveyor separation of magnetic minerals from less magnetic minerals

Magnetic separators for mineral separation in a mining dove high intensity disc electromagnetic separators are designed for separation of dry granular mixtures of magnetic minerals from nonmagnetic as well as elective separation of one weakly magnetic mineral from another and perfectly suit the following applications

Magnetic separation takes advantage of the differences in magnetic properties of minerals most minerals fall into one of these categories ferromagnetic paramagnetic and diamagnetic among these categories ferromagnetic materials show the highest magnetic susceptibility hence they can be easily separated by the magnetic separation method

Dove high intensity disc electromagnetic separators are designed for separation of dry granular mixtures of magnetic minerals from nonmagnetic as well as elective separation of one weakly magnetic mineral from another and perfectly suit the following applications concentration of dry granular minerals such as ilmenite garnet monazite wolframite columbite tantalite etc

Magnetic separation for the mining industry umsmin magnetic separation for the mining industry magnetic separation for the mining industry is a good option for recycling because a lots of minerals are just out of magnetic separation method in mining makabsworg magnetic separation for the mining industry

Overband magnetic separator jaykrishna magnetics pvt ltd has developed overband magnetic separator to separate ferrous impurities from any kind of minerals overband magnetic separator also called as obms it is highly recommended for the highest possible degree of separation in mineral mining industry with longterm magnetic stability

Jul 10 2019 description of permanent drum magnetic separator the dry type permanent drum magnet magnetic separator is a magnetic preseparation device for magnetite ore mainly deployed in the preselection stage before the fine crushing or grinding process to removes gangue and surrounding rock tailings discharging rate is about 10

And a slon1000 vertical ring and vibrating highgradient magnetic separator has been developed for dry magnetic separation it can treat weakly magnetic minerals in the size range 020 mm and has been used in industry for upgrading roasted kaolin of 002 mm by removing the impurities of oxidized iron ore and other weakly magnetic minerals

Magnetic mineral separation techniques are invariably selective and not fully representative of the grain size and composition of magnetic minerals present in the sample however magnetic separation may be necessary for semtem xray moss or chemical analyses the importance of fine sd grains as remanence carriers emphasizes the

Global magnetic separator market for mining industry overview magnets play an important role in the mining and quarrying industry a magnetic separator is an industrial equipment that generates a powerful magnetic flux by attracting the magnetic particles such as ferrous minerals or impurities

Mining magnetic and electrostatic separation magnetic separation is a wellestablished separation technique and has become increasingly popular as new equipment on the market enhances the range of separations possible it is an attractive process choice because of low capital and operating costs and the lack of chemicals to cause

Thanks to technical office structure magnetense can offer to its customers a service not only related to magnetic separation but also to the whole production process in mining industry in this page you can find more indepth information about each one of our magnetic separation systems for mining industry

Magnetic separators for mineral separation in a mining dove high intensity disc electromagnetic separators are designed for separation of dry granular mixtures of magnetic minerals from nonmagnetic as well as elective separation of one weakly magnetic mineral from another and perfectly suit the following applications

Gn separation and conveying equipment is widely used in the separation and conveying of ore and minerals in the mining industry gn mining shale shakers are used for the separation of ore and minerals including coarse sieving mining shale shaker and fine separation mining shale shaker

WhatsApp)

WhatsApp)